36

JOTUN GROUP

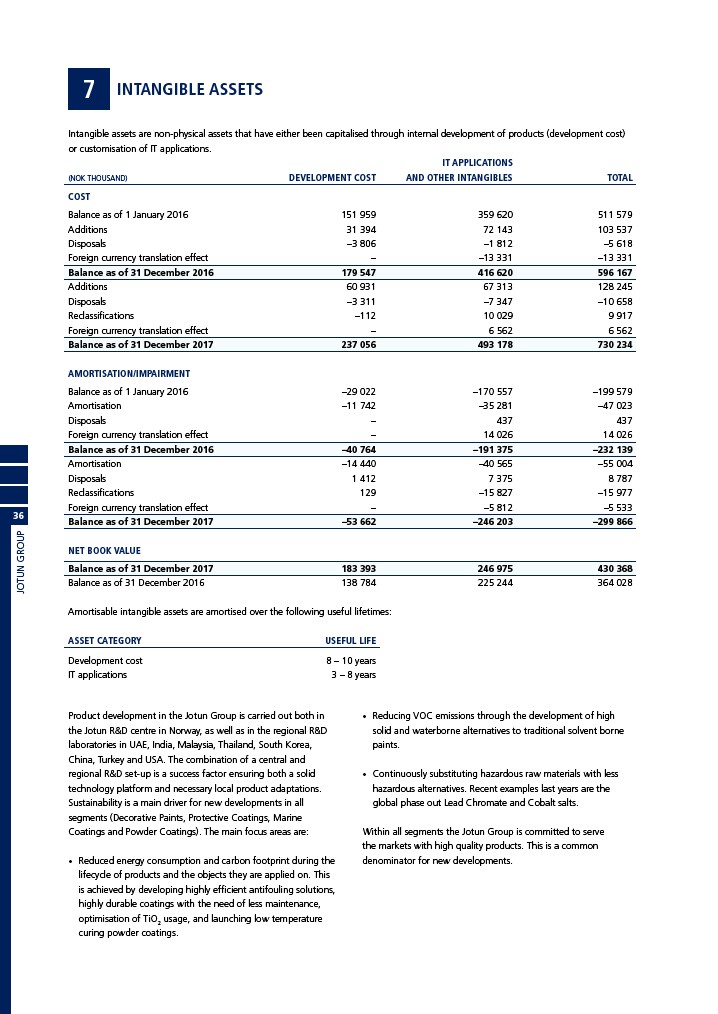

7 INTANGIBLE ASSETS

Intangible assets are non-physical assets that have either been capitalised through internal development of products (development cost)

or customisation of IT applications.

IT APPLICATIONS

(NOK THOUSAND) DEVELOPMENT COST AND OTHER INTANGIBLES TOTAL

COST

Balance as of 1 January 2016 151 959 359 620 511 579

Additions 31 394 72 143 103 537

Disposals –3 806 –1 812 –5 618

Foreign currency translation effect – –13 331 –13 331

Balance as of 31 December 2016 179 547 416 620 596 167

Additions 60 931 67 313 128 245

Disposals –3 311 –7 347 –10 658

Reclassifications –112 10 029 9 917

Foreign currency translation effect – 6 562 6 562

Balance as of 31 December 2017 237 056 493 178 730 234

AMORTISATION/IMPAIRMENT

Balance as of 1 January 2016 –29 022 –170 557 –199 579

Amortisation –11 742 –35 281 –47 023

Disposals – 437 437

Foreign currency translation effect – 14 026 14 026

Balance as of 31 December 2016 –40 764 –191 375 –232 139

Amortisation –14 440 –40 565 –55 004

Disposals 1 412 7 375 8 787

Reclassifications 129 –15 827 –15 977

Foreign currency translation effect – –5 812 –5 533

Balance as of 31 December 2017 –53 662 –246 203 –299 866

NET BOOK VALUE

Balance as of 31 December 2017 183 393 246 975 430 368

Balance as of 31 December 2016 138 784 225 244 364 028

Amortisable intangible assets are amortised over the following useful lifetimes:

ASSET CATEGORY USEFUL LIFE

Development cost 8 – 10 years

IT applications 3 – 8 years

Product development in the Jotun Group is carried out both in

the Jotun R&D centre in Norway, as well as in the regional R&D

laboratories in UAE, India, Malaysia, Thailand, South Korea,

China, Turkey and USA. The combination of a central and

regional R&D set-up is a success factor ensuring both a solid

technology platform and necessary local product adaptations.

Sustainability is a main driver for new developments in all

segments (Decorative Paints, Protective Coatings, Marine

Coatings and Powder Coatings). The main focus areas are:

• Reduced energy consumption and carbon footprint during the

lifecycle of products and the objects they are applied on. This

is achieved by developing highly efficient antifouling solutions,

highly durable coatings with the need of less maintenance,

optimisation of TiO2 usage, and launching low temperature

curing powder coatings.

• Reducing VOC emissions through the development of high

solid and waterborne alternatives to traditional solvent borne

paints.

• Continuously substituting hazardous raw materials with less

hazardous alternatives. Recent examples last years are the

global phase out Lead Chromate and Cobalt salts.

Within all segments the Jotun Group is committed to serve

the markets with high quality products. This is a common

denominator for new developments.