EMPLOYEES AND THE WORKPLACE

47

included to ensure that similar occurrences do not take place at

other Jotun sites. The case studies are shared throughout the

network, demonstrating the Group approach to a continual

process of learning and improvement.

Zero tolerance

In an industrial environment characterised by the use of

chemicals, including solvents, fires pose the greatest threat

for Jotun operations. As such, Jotun follows a zero tolerance

policy whereby every incident and potential incident is fully

documented and investigated to learn from experiences and

build expertise. This complements a structured fire prevention

programme that includes thermographic surveys of sites, fire

risk assessments, regular inspections of fire fighting systems,

and continual training and e-learning initiatives.

Maintaining standards

The HSEQ Management System is firmly established and a rolling

cycle of audits will ensure that optimal standards are maintained.

Each site will be audited once every three years, with the option

of prioritising those where greater risk potential is identified.

In 2018, a total of 10 HSEQ audits were conducted, with a

further 11 planned for 2019.

Further developments in 2018

E-learning – introduction of new e-learning modules within

‘working permits’, reducing the likelihood of accidents while

undertaking high-risk, non-routine work.

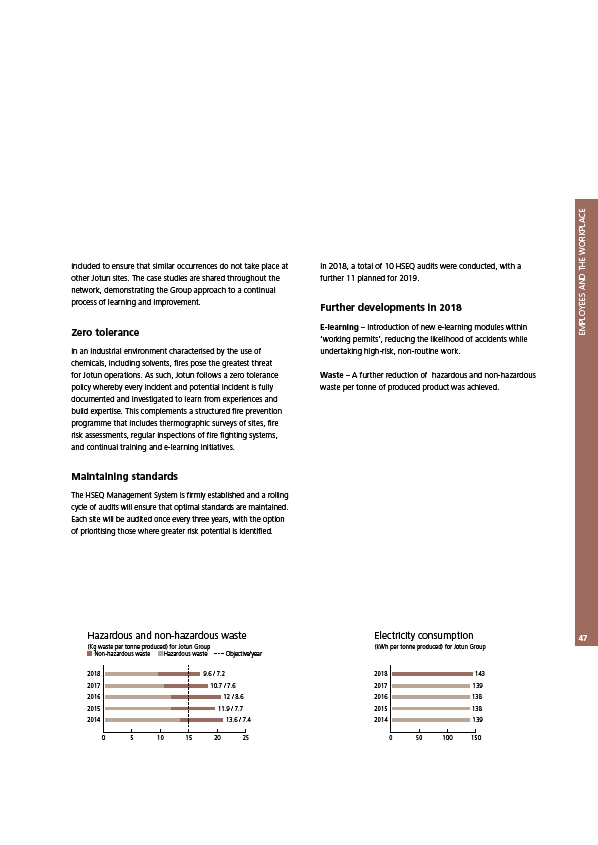

Waste – A further reduction of hazardous and non-hazardous

waste per tonne of produced product was achieved.

Electricity consumption

(kWh per tonne produced) for Jotun Group

2018 143

0 50 100 150

2017

2016

2015

2014

139

138

138

139

Hazardous and non-hazardous waste

(Kg waste per tonne produced) for Jotun Group

Non-hazardous waste Hazardous waste Objective/year

2018 9.6 / 7.2

0 5 10 15 20 25

2017

2016

2015

2014

10.7 / 7.6

12 / 8.6

11.9 / 7.7

13.6 / 7.4