EMPLOYEES AND THE WORKPLACE

46

The path to improvement

Jotun follows a long-term global, mandatory and integrated HSEQ strategy to build a uniform culture where

safety, quality and environmental care are central to everything we do.

Jotun’s high standards are the result of an established,

structured and responsible approach that constantly evolves in

the quest for incremental improvement.

From Jotun Group management down and across our

global network, employees are trained to achieve optimal

levels of care, safety and efficiency, targeting the objective

of zero incidents, fires, claims and spills. Jotun’s new HSEQ

Management System, which completed its full implementation

last year, is the cornerstone of our strategy.

This ensures that every production company within the Group

delegates responsibilities according to 14 different elements (i.e.

risk management, quality, and product safety), working towards

the same universal goals.

The result of our efforts from 2018 demonstrates that Jotun

continues to move in the right direction.

‘I Care’

Every Jotun company runs one mandatory ‘I Care’ campaign

a year – focusing on raising HSE awareness and reducing

operational risk. In addition, each company must also run two

further campaigns tailored to address their individual needs and

risk environments. The initiatives seek to engage all employees

and influence behaviour, with the companies required to report

on their impact and effectiveness at Group level.

The best local ideas are shared throughout the Group, while the

standout mandatory campaign is recognised with the ‘I Care

Campaign of the Year’ award. In 2018 the mandatory activity

focused on the ‘man-machine’ interface to build awareness of

risk and reduce injury potential. In 2018, Jotun Thailand won

the overall campaign of the year title.

‘Lessons Learned’

All incidents of high-risk potential, such as fires, are reported,

analysed and followed up to mitigate the possibility of

future reoccurrence. ’Lessons Learned’ case studies are key

improvement tools.

‘Lessons Learned’ document an event’s chronology, its cause,

the corrective actions to be taken, and preventative actions to

avoid repeat incidents. Finally ‘expected actions from all’ are

HSEQ

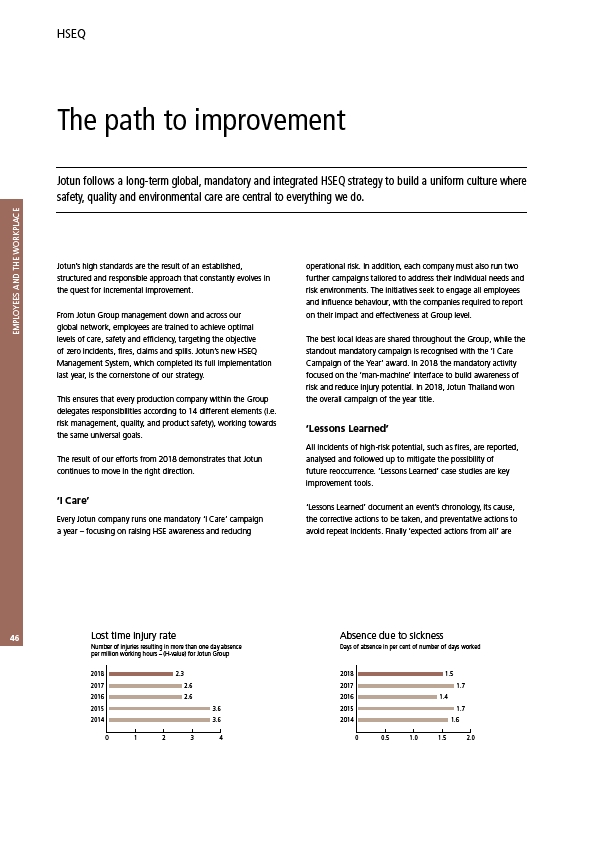

2018 2.3

0 1 2 3 4

2017

2016

2015

2014

2.6

2.6

3.6

3.6

2018 1.5

0 0.5 1.0 1.5 2.0

2017

2016

2015

2014

1.7

1.4

1.7

1.6

Lost time injury rate

Number of injuries resulting in more than one day absence

per million working hours – (H-value) for Jotun Group

Absence due to sickness

Days of absence in per cent of number of days worked