56

ENVIRONMENTAL COMMITMENT

ENSURING ENVIRONMENTAL

PERFORMANCE

Green is Jotun’s favourite colour. We are committed to utilising greener materials, production methods and

product offerings, helping our customers improve their own environmental performance, and safeguarding

the world around us.

Jotun is committed to continually improving its environmental

performance. The Group follows a long-term strategy that

focuses on reducing waste while optimising energy efficiency.

We identify best practices locally, such as installing light tunnels,

solar panels and treating waste water on-site, and introduce

them internationally, while setting stringent standards on a

Group level for all sites to follow.

THE STRUCTURE TO SUCCEED

in 2015, the goal to reduce waste was formalised with the

roll out of Jotun’s HSEQ Management System, concerning

environmental expectations, systems, reporting and support tools.

This describes requirements to ensure the correct measures are

implemented to protect the environment locally, prevent spills

and accidental emissions, handle waste effectively, and promote

energy efficiency and awareness.

A central focus concerns the structure to support Jotun’s overall

HSEQ targets, with clear key performance indicators (KPIs)

reporting required from each site, namely, waste in kg/tonne

produced (%), total waste (hazardous and non-hazardous),

energy kWh per tonne produced for liquid paints, and energy

kWh per tonne produced for powder coatings.

The management and employees on each site are expected to

own and participate in this environmental commitment, taking

part in activities such as site environmental risk assessments,

training and environmental compliance.

WORKING TOGETHER

Achieving optimal environmental performance is an integrated

part of Jotun’s daily operational objectives. This clear, simple

and structured approach ensures that every facility, team and

individual understands and positively contributes to achieving

our overall Group objectives.

In 2018, Jotun will continue its drive to reduce waste, targeting

the use of less packaging, with, for example, increased raw

material deliveries from tankers rather than in bags, and a push

through the purchasing department to consider every purchase

in the context of product Life Cycle Analyses and, where

relevant, Environmental Product Declarations.

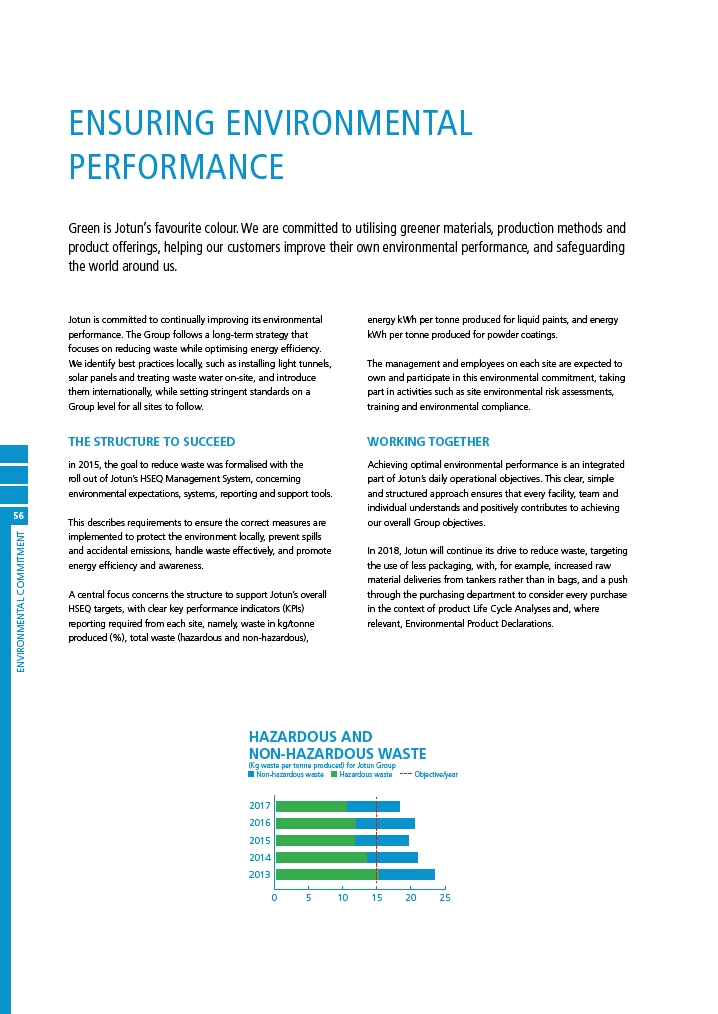

HAZARDOUS AND

NON-HAZARDOUS WASTE

(Kg waste per tonne produced) for Jotun Group

Non-hazardous waste Hazardous waste Objective/year

0 5 10 15 20 25

2017

2016

2015

2014

2013