50

EMPLOYEES AND THE WORKPLACE

SAFETY ALWAYS COMES FIRST

Different countries, different challenges, but the same stringent systems, procedures and standards. Jotun’s

diverse operational facilities are united by a carefully maintained culture of safety.

Safety is a cornerstone of all Jotun operations. The Group

continually develops and improves the management system

that sets uniform global standards, while supporting individual

operations in their efforts to address issues and improve

performance on a local level.

In 2017, safety at new Jotun facilities was a key focus, with

factory projects entering the production phase in Russia,

Myanmar, Malaysia and in the Philippines.

GETTING A HEAD START ON SAFETY

Jotun works hand in hand with local teams to ensure that

operational facilities can maintain optimal safety standards from

day one. New sites are constructed with safety at their hearts,

built to the highest engineering standards, with 5S requirements

now integrated within factory layouts, while facilities undergo a

pre-operations assessment and HSEQ audit before start-up.

A Jotun support team joins the local organisation to ensure

that all safety equipment, systems and procedures are fit for

purpose, while identifying risk areas, such as hazardous areas,

fire-fighting capabilities and the control of static electricity.

Once all criteria have been satisfied, the team stays in place

for an initial production phase to oversee operations and verify

safety standards. A further HSEQ audit is conducted one year

after startup to ensure the maintenance of required standards.

BUILDING SAFETY IN MYANMAR

Jotun refuses to compromise on safety. While constructing the

new factory in Myanmar, the project team had to work hard to

communicate the benefits of our practices and convince local

workers to comply with Jotun’s stringent safety standards.

A multi-faceted approach was used, with the project team

on site every day to set a positive safety example and address

challenge areas. Daily toolbox meetings with contractors

highlighted required safety practices, while visual aids (such

as posters) on site used positive, simple messages to reinforce

understanding of expected standards. All staff conducted

induction safety training and were encouraged to maintain

standards, with dedicated awards schemes for ‘HSE employees

of the month’.

The end result of this consistent, clear and structured approach

to safety was a project completed on schedule, with zero lost

time injury (LTI) recorded across almost 800 000 working hours.

The Myanmar production facility was officially opened in

November 2017.

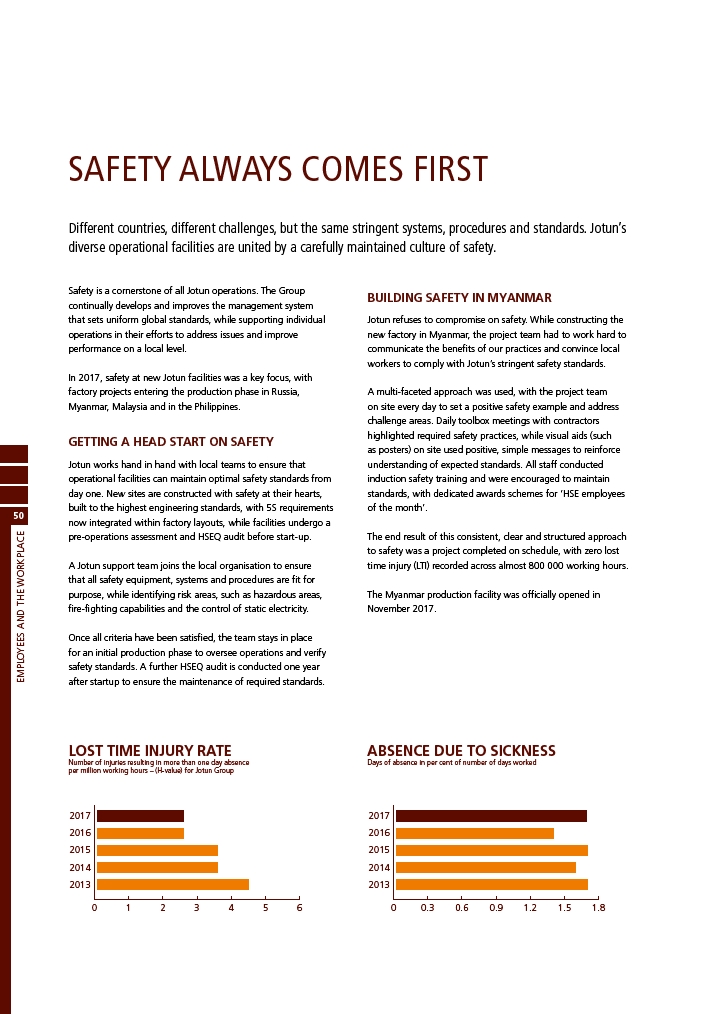

0 1 2 3 4 5 6

2017

2016

2015

2014

2013

0 0.3 0.6 0.9 1.2 1.5 1.8

2017

2016

2015

2014

2013

LOST TIME INJURY RATE

Number of injuries resulting in more than one day absence

per million working hours – (H-value) for Jotun Group

ABSENCE DUE TO SICKNESS

Days of absence in per cent of number of days worked